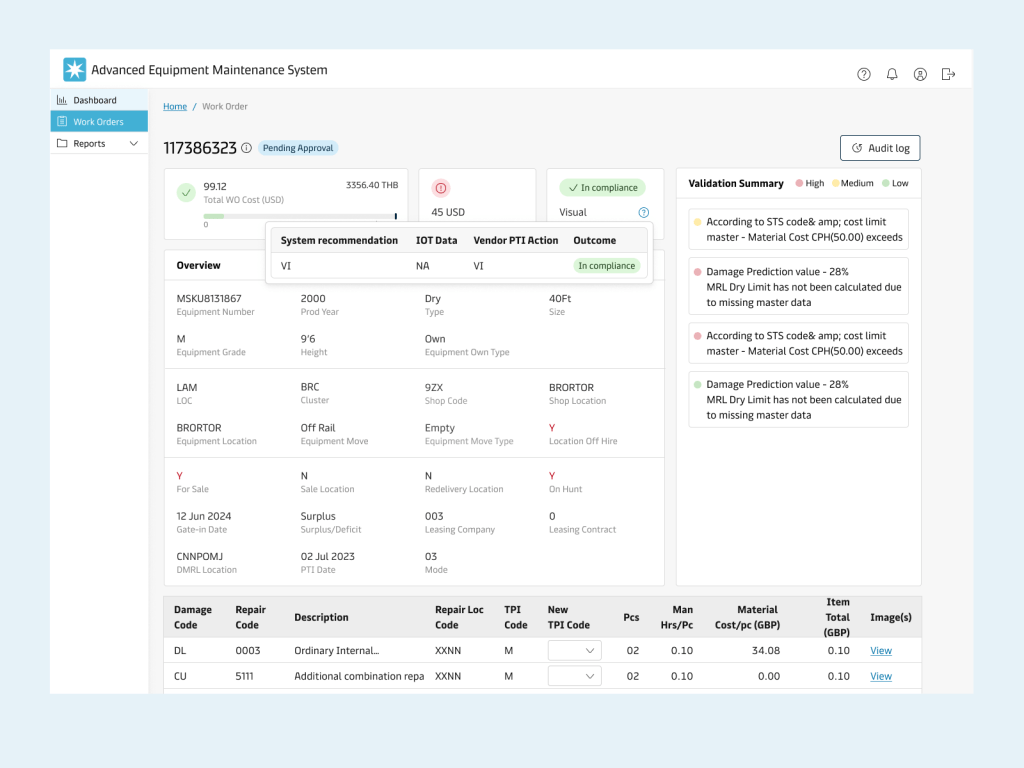

AEMS is an asset management platform which enables equipment repair workflow by serving multiple user groups. The vendors responsible for capturing damages done to the equipment and subsequent repairs can quickly and efficiently create work orders while the business users can review the submitted work orders for repair completion. The EMR (Equipment maintenance & repair) team can regularly audit the vendor performance to evaluate compliance deviation and take relevant actions.

To comply with my non-disclosure agreement, I have omitted and obfuscated confidential information in this case study. The information in this case study is my own and does not necessarily reflect the views of Maersk.

My Role

UX Designer, Researcher

Timeline

24 months

Tools Used

Figma, Miro, Internal feedback system

Brief

Every year Maersk spends about $410 million (based on 2022 data) on container repair and maintenance activities. These repairs are performed by 3rd party vendors on completion of a booking. Due to multiple gaps in the legacy system there were leakages in business. Vendors submitted excessive repairs and due to lack of validations Maersk loses around $20-40 million every year. With huge volumes coming in on the approvers side, this problem increased further due to lack of visibility on key data points leading to poor quality approvals.

Discovery

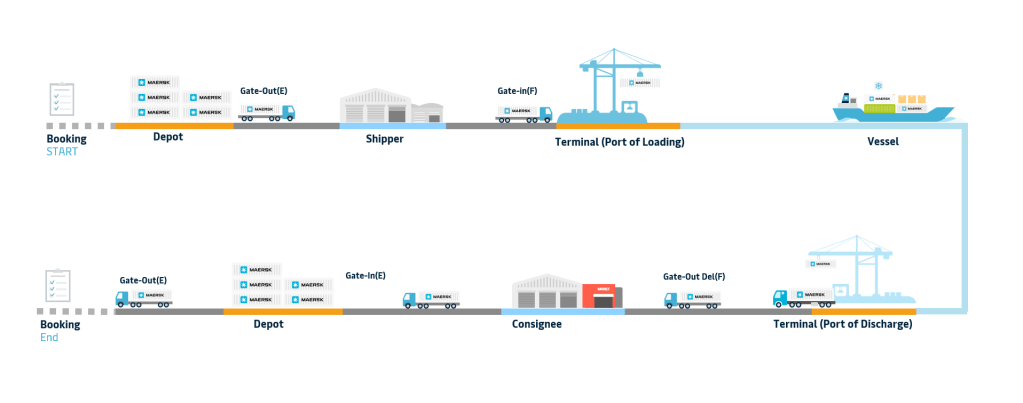

The shipping and logistics domain was new to me at the time, in order to understand the business and operations I visited a container repair depot in Chennai, India. The purpose of the visit was to shadow the vendors to understand how containers enter the depots and are repaired. Vendors are 3rd party shops contracted by Maersk to repair containers at different locations across the globe.

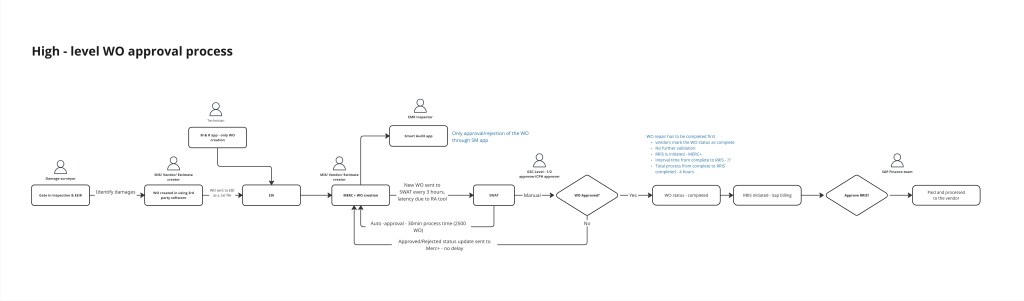

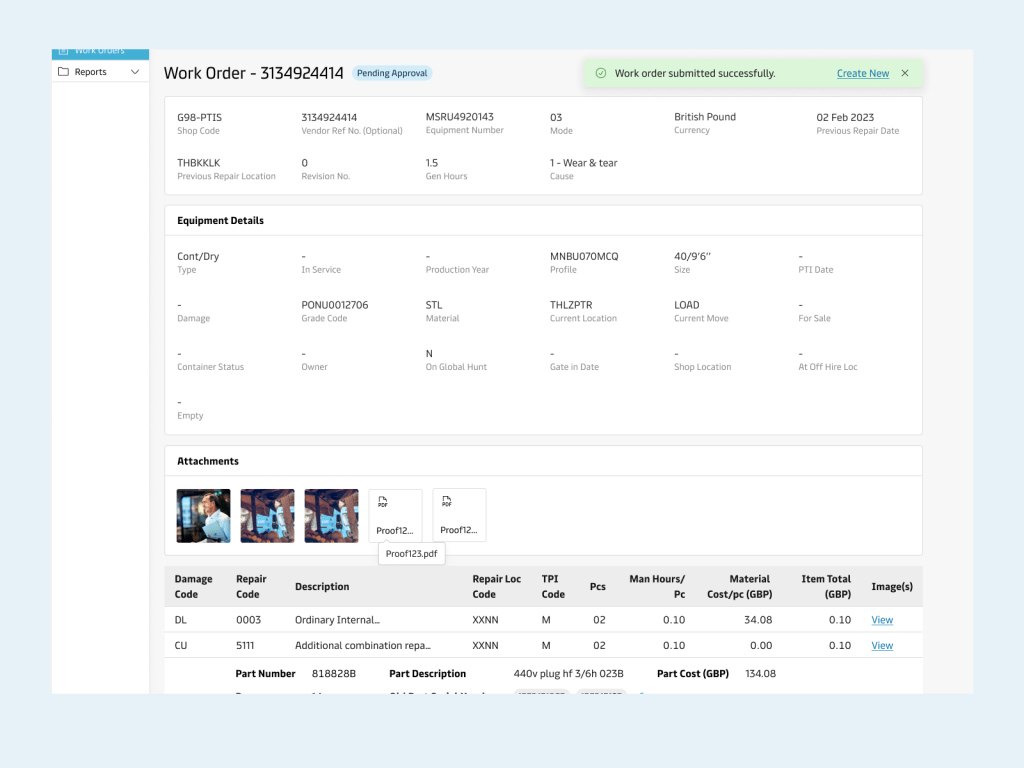

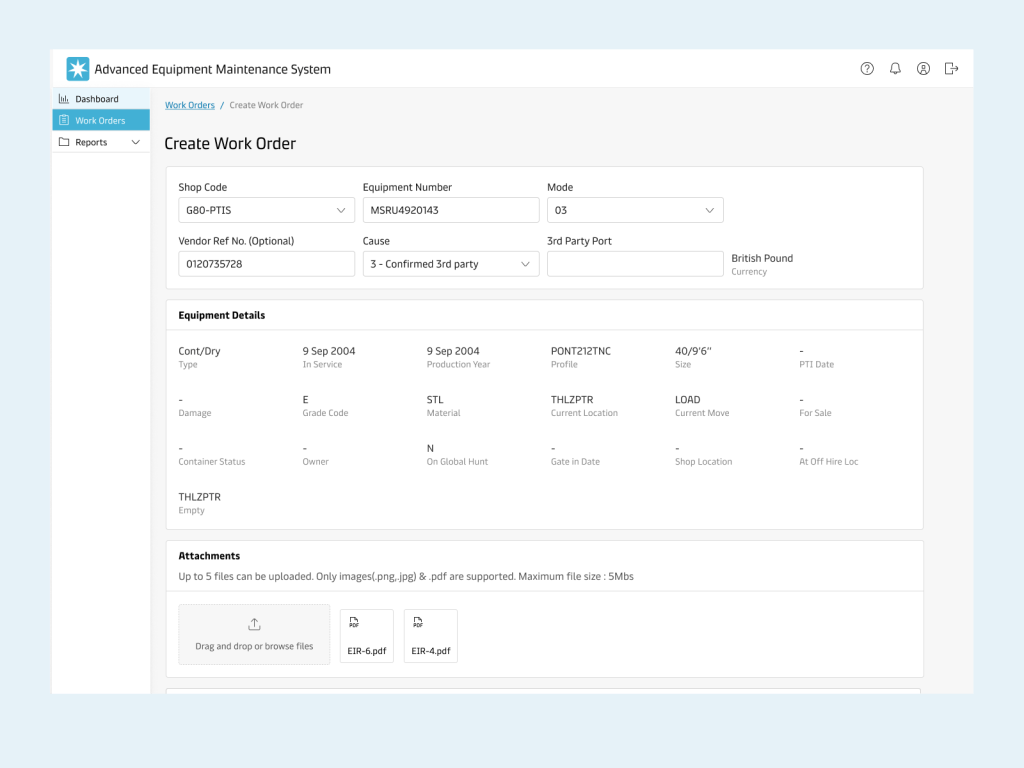

The repair process is divided into two steps; inspection & work order submission. The equipment inspectors inspect a container at the time of Gate-in and document the damages in a survey report. The inspectors would also captures images as proof of damage in an app called EIR. Another shop user is responsible to digitize these reports and create work orders using the legacy system.

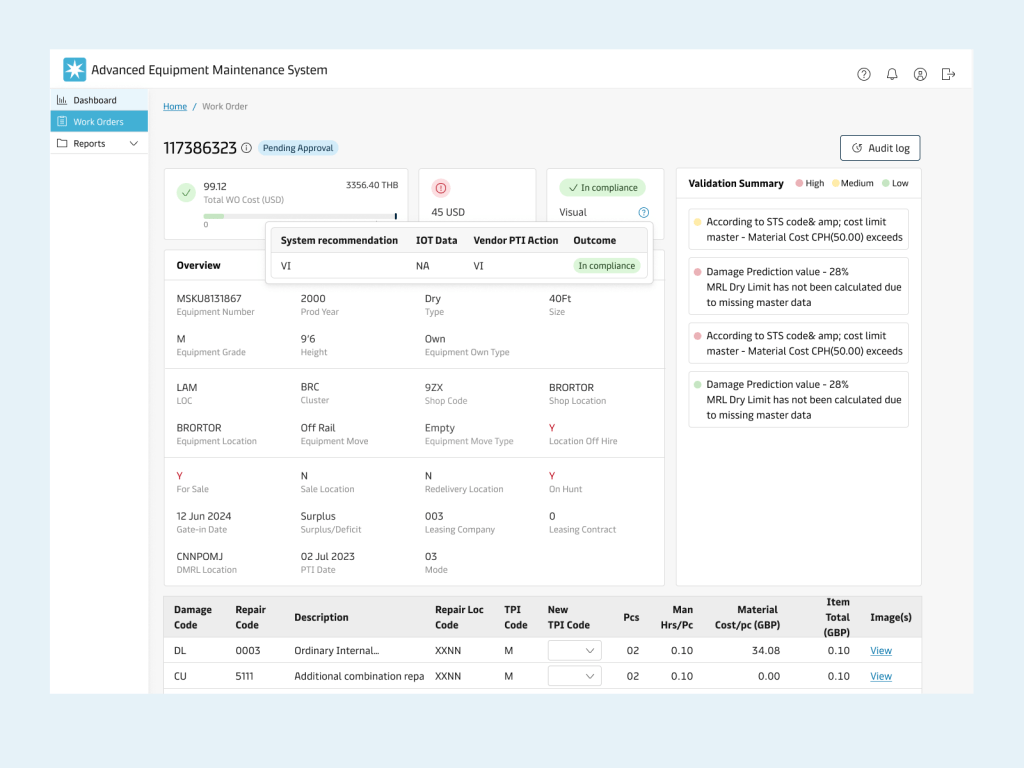

The submitted work order is then received by the auto-approval engine which runs around 85 validations to approve nearly 65% of the work order volume, remaining 35% would be approved manually by the business users. The business users are expected to clear out daily volumes in their respective queue to keep the system running smoothly.

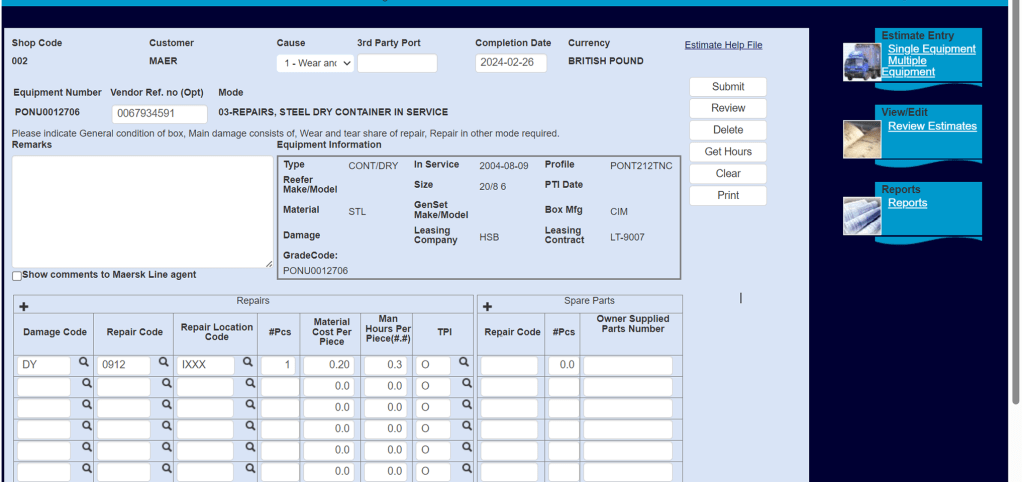

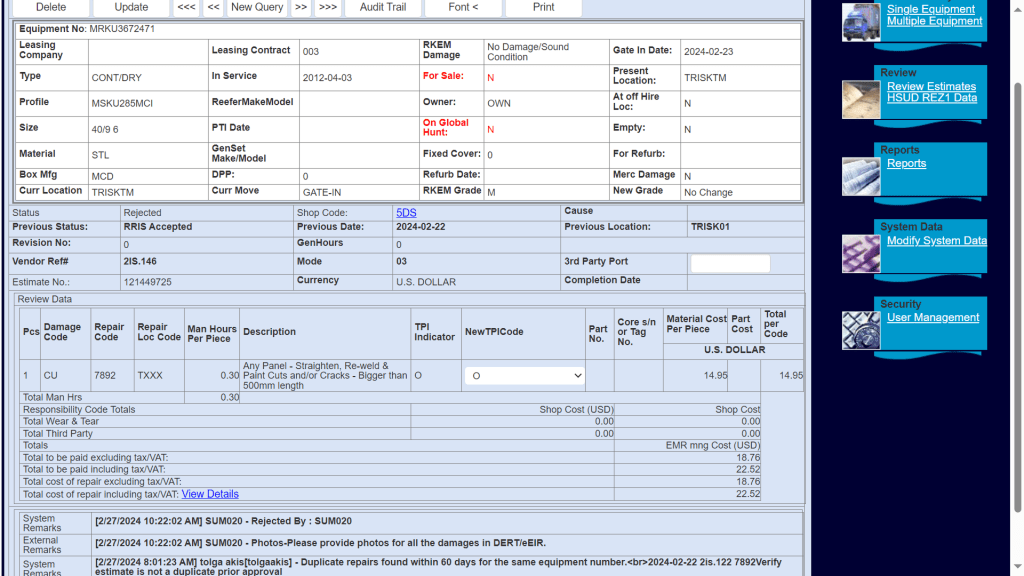

Legacy Systems Snapshot

Existing Ecosystem

Research findings/insights

Vendors

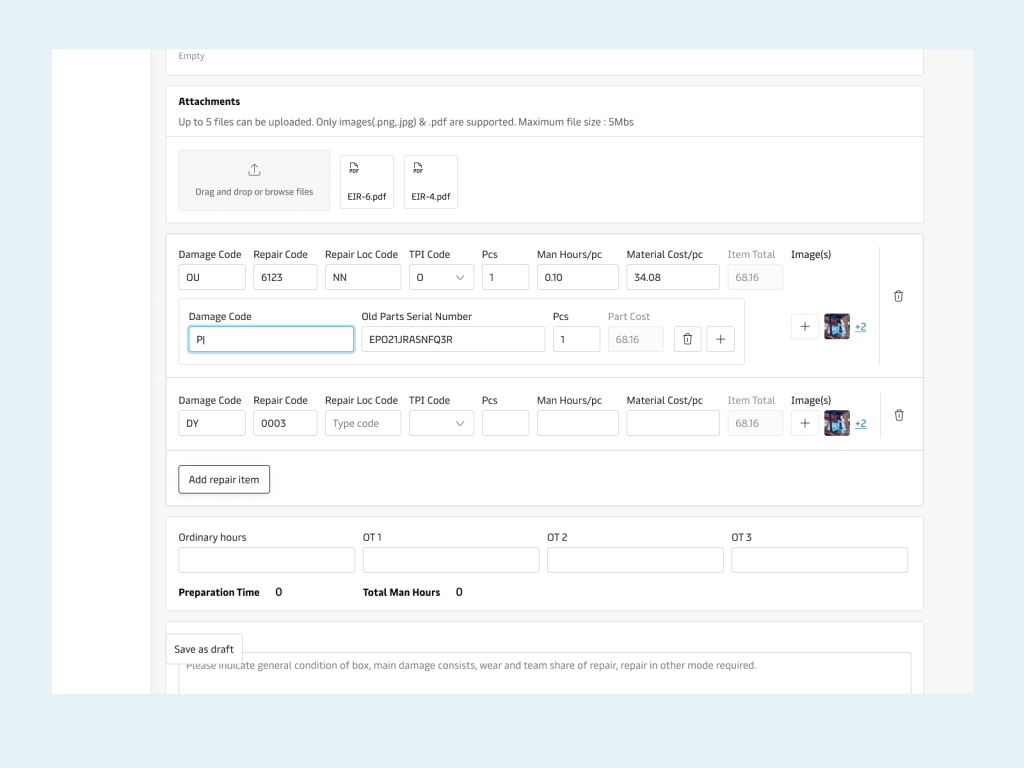

- The legacy system was operated end to end with the keyboard only. The shop users found switching between mouse & keyboard cumbersome as daily volumes could be as high as 250 work orders.

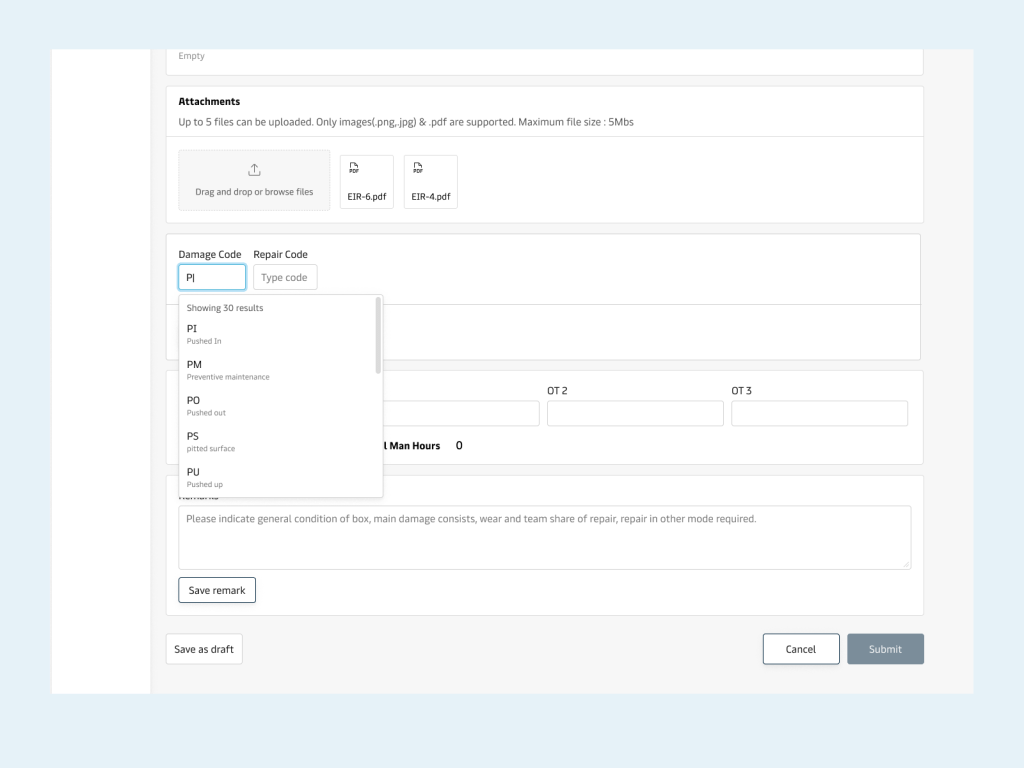

- The legacy system came with a huge learning curve due to lack of contextual help and was not designed for a new user who would require time to learn and pick up jargon as well as remember repair codes by heart.

- A cumbersome menu structure with confusing visuals.

- Lack of search function in lists with more than 1000 items. Due to large number of values, users were forced to rely on an external excel to filter out specific values.

- Lack of in-line error handling led to confusion.

- Mandatory fields were not marked/highlighted which increased users’ overhead to remember them.

- Use of unclear labels/terminology.

- Switching between multiple applications leading to app fatigue.

Business Users

- The existing approval system gave no visibility on city/cluster/region level volumes to prioritize approval volumes accordingly.

- No business user could monitor their daily/monthly performance.

- Dependency on other tools like DERT/EIR to compare entered repairs with damage proofs.

- No validation message for an excessive repair submitted by the user.

- Use of semantic colours for buttons on the screen led to confusion.

Problem Statement

How might we simplify and accelerate the end-to-end container repair process—resolving data gaps, reducing manual approvals, and improving real-time communication—so vendors can complete repairs promptly and keep Maersk’s container fleet ready for customers?

How might we provide Maersk customers with fast, reliable access to containers that meet their exact specifications—eliminating long confirmation times, last-minute booking cancellations, and quality issues—so they can plan logistics confidently and experience consistently high service?

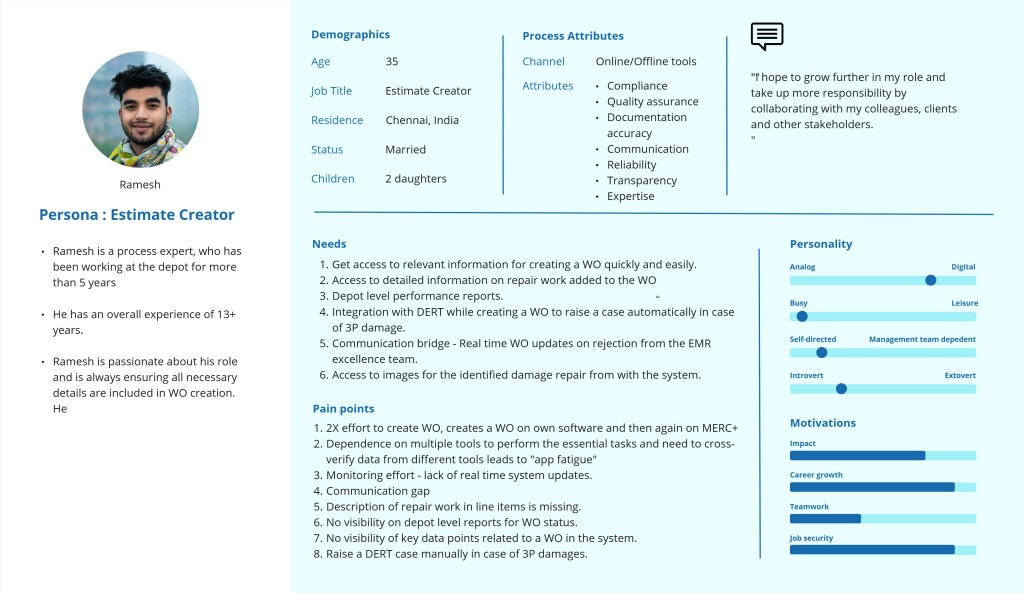

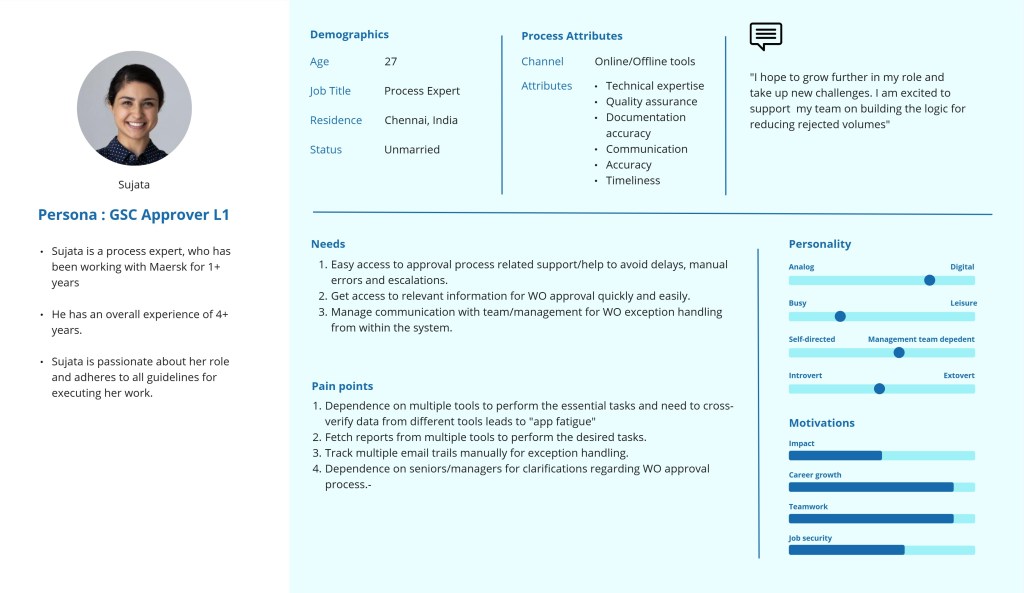

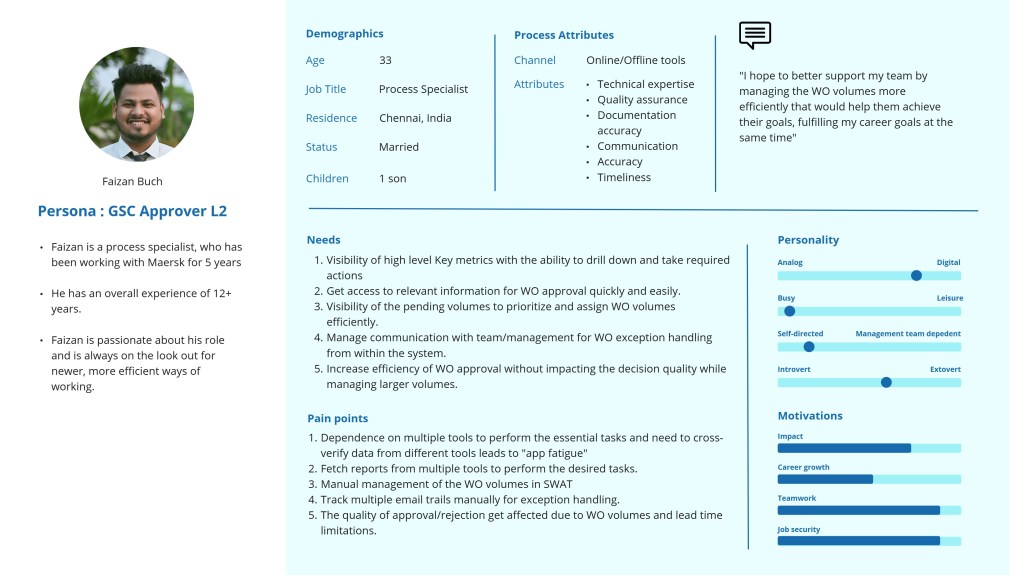

Personas

Since different users had different roles to run the entire equipment maintenance and repair system, I came up with different personas for business user and vendors.

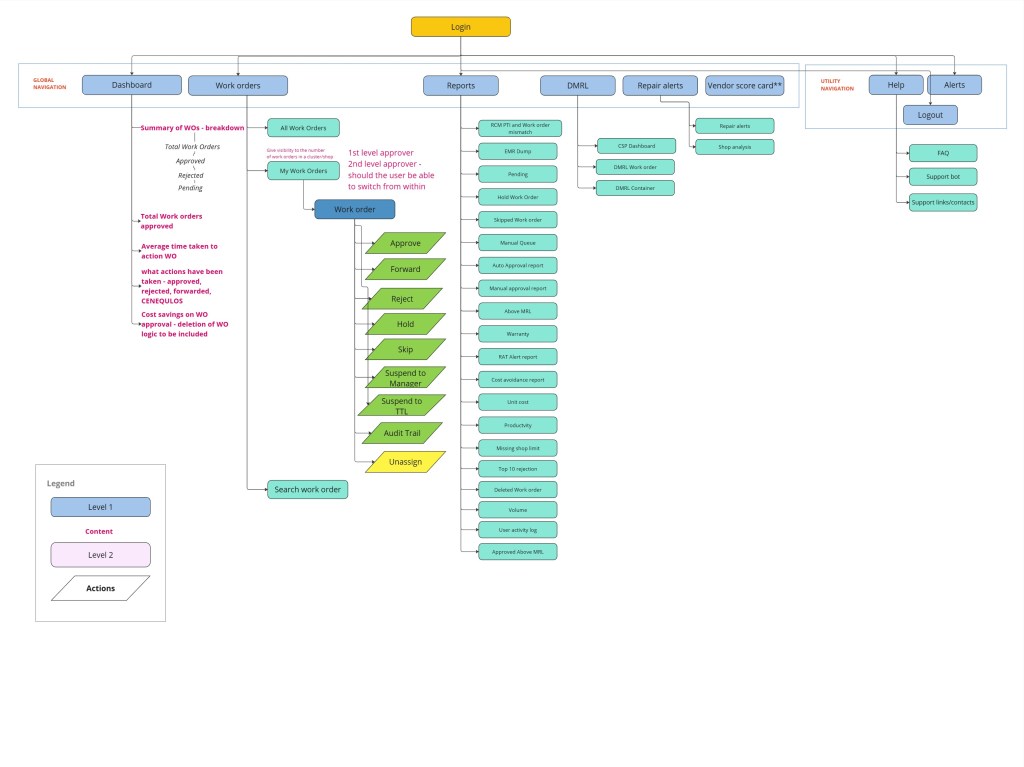

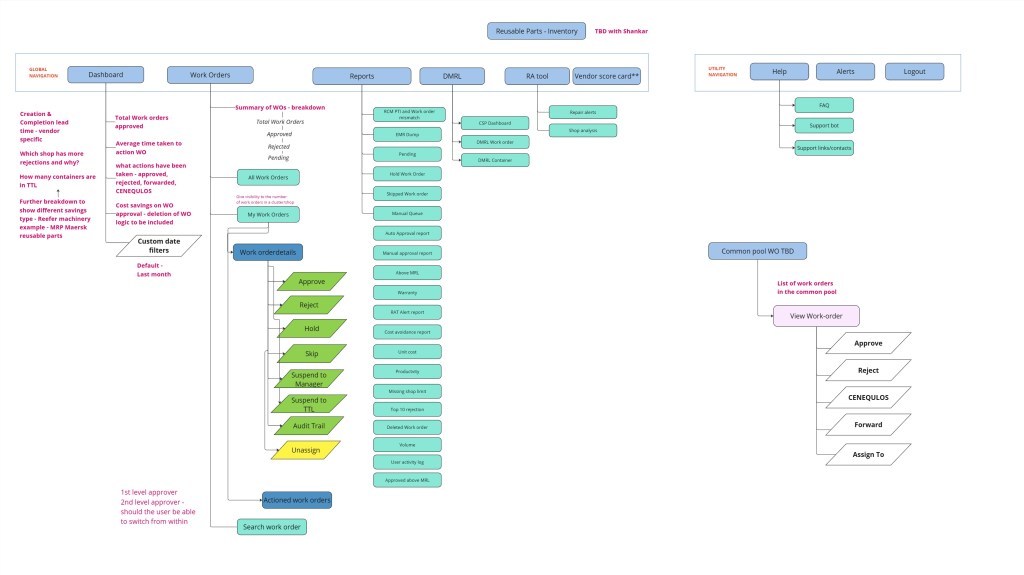

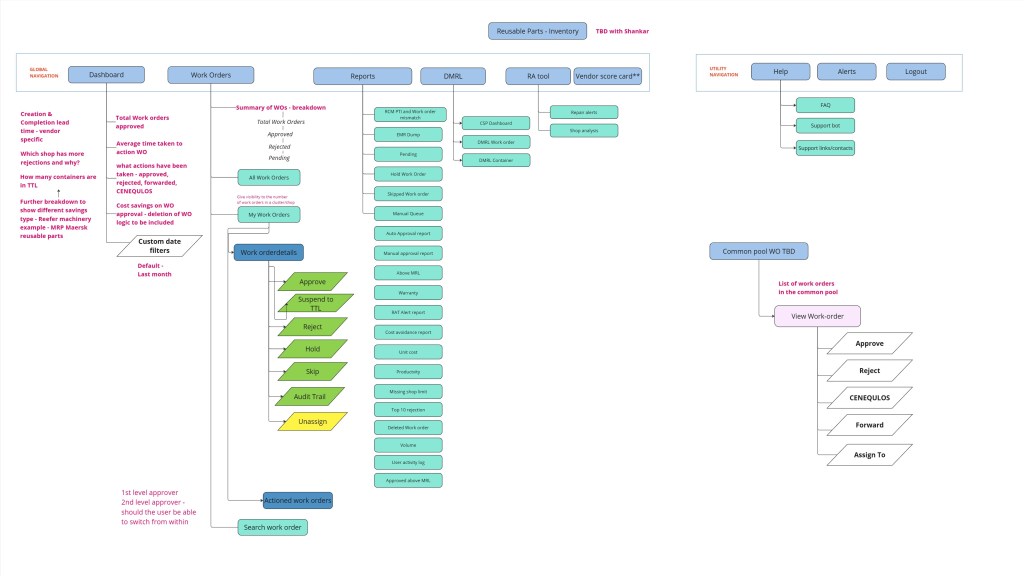

Information Architecture

Different roles would be able to view different features and functionalities hence I structured the required features and functionalities into information architectures according to respective roles.

Design Solution

Shop users

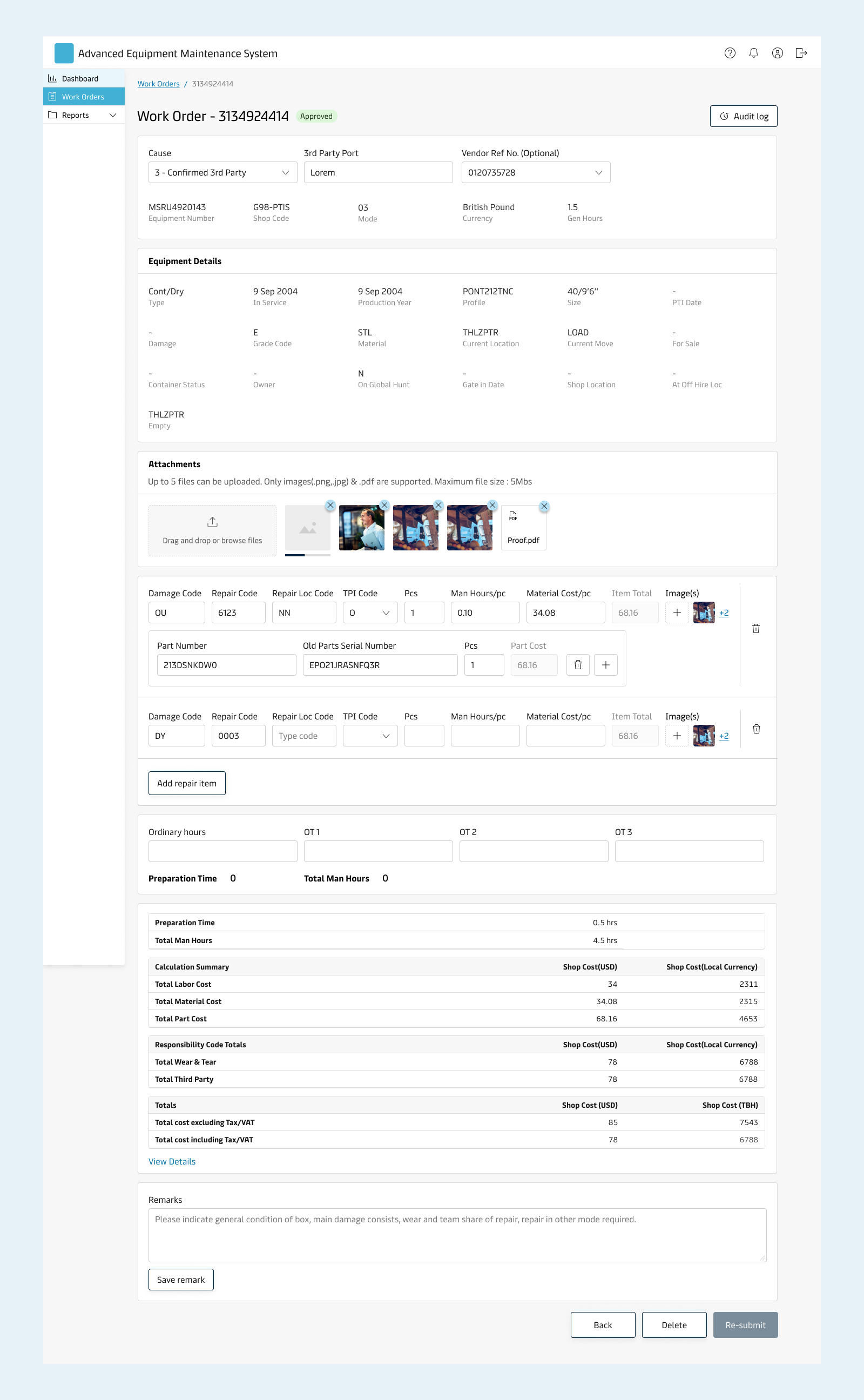

- The lengthy work order form was broken down into smaller sections which are exposed progressively. This reduced clutter and allowed user to focus on one section at a time.

- Addition of in-line error handling saved time on work order submission.

- Additional validations to warn the user in case they added an unnecessary repair.

- With EIR integration the users can now link images directly with each repair line item before submitting, thus reducing back and forth between vendors and business users for work order approvals.

- A list view on logging in with rejected work order status filtered by default for them to review and take action.

Business Approvers

- Visibility of PTI compliance for reefer containers.

- Validation summary categorises & highlights the high, medium and low level alerts.

- The users could now review the repairs and images on a single platform.

Feedback and Testing

I tested the initial designs with 11 Shops across various countries and with key stakeholders to identify gaps. The initial approach passed however, we had to iterate the designs twice due to gap in understanding of the system usage. These iterations saved us a significant development effort as the feedbacks were incorporated well before the development began.

At the UAT stage there were very minor feedbacks with multiple requests to add more features like bulk work order creation and addition of reports feature for internal auditing.

Post development SUS and NPS scores were also calculated with the help of our internal insights hub platform.

Impact & Results

Shops Onboarded

662 shops

Surpassed the target of onboarding 475 shops by Q3 2025.

Volumes Covered

95%

Onboarded shops cover more than 95% of the total work order volume.

Rate of Adoption

96%

96% live shops are using AEMS to submit 100% of their work order volume.

Auto- Approval Rate

74%

Increased auto approval rate by 7% compared to 67%

Unnecessary Repairs

$8 Million

$8m savings by eliminating unnecessary repairs (through PTI compliance, live reefer repair compliance & duplicate repair compliance)